Tatami has many variations, the materials vary, this paired with other factors means there is great diversity in the product.

In order to choose appropriate tatami for your needs it is important to select the correct omote (cover) and toko (base).

1 How to choose ‘tatami-omote’

Igusa produced in Japan

Tatami-omote made in Japan

-

Japanese omote is the best quality in the world, while price varies the durability and aesthetic far out weight cheaper options.

Igusa produced in Japan is the highest quality, it maintains its elasticity, durability, and ages well without fading and variation in color.

-

There are many types, ranging from a typical selection to the luxury product

Igusa grown and made in Japan still has grades of quality and type.

Motoyama Tatami only buys igusa of consistent quality, directly from reliable producers, our tatami-omote are produced using igusa that undergoes rigid evaluation to maintain its classification.

We produce all levels of Japanese tatami. There is correct fit for every situation, from very high-end to regular use.

Imported products are more affordable

-

Rapidly spreading due to their lower price

Igusa produced overseas is becoming more common in apartments and rental housing because of its lower cost.

-

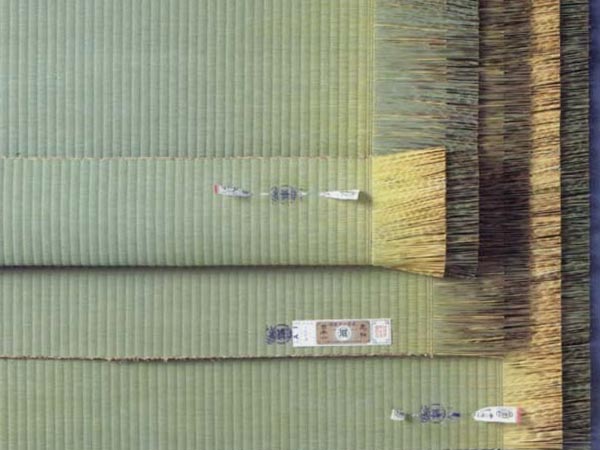

Comparison between Igusa produced in Japan and Imported Igusa

Top image: Produced in Japan / Bottom image: Imported product

In recent years, the quality of imported igusa has improved. This is largely due to technical support from Japanese companies. However, generally speaking, the quality is still significantly lower, and there are several notable differences when compared with igusa produced in Japan:

- Imported igusa is harvested approximately one month earlier. Because it is not fully matured, the surface is more fragile and less durable. Inspection and classification of imported products are not stringent, so the density and shape of the igusa vary greatly when used. This results in an uneven surface and dramatically reduces the longevity of the omote.

- Drying time is much shorter to support high-volume production. This high production volume and overseas shipping also require the igusa to be dried more intensely to prevent mold. Over-drying reduces both elasticity and durability.

- Japan has strict classification standards, but these are not adhered to in imported products. As a result, overall quality is lower and color stability is poor. To achieve color consistency similar to Japanese products, a coloring process is often used, which damages the natural material. When colored igusa is used, the dye may wear off and transfer to clothing. This process also prevents the igusa from developing the natural golden patina expected in Japanese tatami, instead leading to an unattractive, sunburnt appearance.

-

Recommended Uses for Imported Products

- Imported products do have suitable applications. They are well suited for rental properties, where the omote needs to be replaced frequently.

- They are also appropriate for spaces where flooring is subject to heavy use and frequent damage, such as children’s rooms.

- Higher-grade imported products are acceptable for high-traffic areas and, due to their affordability, can be replaced more often.

‘Washi-omote’ (Washi=Traditional Japanese Paper) and ‘Kenzai-omote’ (Kenzai=building material) has wide range of variation and is easy to maintain

-

Easy to take care of, resistant to sunburn, dirt, and mold

This type of omote is made of ‘washi’, traditional Japanese paper, woven and finished like igusa.

It is more durable than igusa. The color only slightly changes, it has no smell and is resistant to mites and mold. One dis-advantage is that washi doesn’t have the air purifying benefits of igusa.

-

There is a wide range of color variation and it will fit numerous types of rooms

Due to the huge range of color you can customize your space.

The number of igusa woven and the weaving string increases the quality

A higher number of igusa used in the weave creates a superior weave

Omote that is dense, thick, and finely woven is durable and beautiful for its life span, aging consistently. As the number of igusa used to create the omote increase, as does the quality and the price.

-

Weave: Cotton is reasonably priced and strong

To weave a large number of igusa four linen threads, or combination of two linen and two cotton threads are used – this creates strength.

In popular (mid-range) product, only two cotton threads are used.

For high end ‘Bingo’, four hemp threads are used.

For Imported omote only one or two cotton strings are used.

The best way to understand and choose tatami-omote is by touch. Feeling the material gives you a better understanding of the quality & difference.

We have samples of various omote. Please contact us.

We also have ‘Ryukyu-omote’, ‘Meseki-omote’, used for ‘Fuchinashi-tatami’ (tatami without borders), and ‘Ryubin-omote’ used for Tokonoma space (alcove). We offer wide range of options depending on your project and your taste.

2 How to Choose Tatami-toko

‘Wara-toko’: 100% natural material, superbly comfortable and durable

Wara (straw) breathes and creates a comfortable living space

Natural base (wara-toko) breathes as it absorbs and releases moisture, which helps control the humidity. Natural base cleans the air in your space, absorbing C02 much more than house plants.

Due to the construction of the base, there are layers of air between the straw, which has natural effect of regulating temperature, this is only achieved with natural materials.Durable and resilient

High quality natural base (wara-toko) is highly durable and resistant to humidity. It has a very long life if you take care of it.

The straw is laid vertically and horizontally, this means it can recover/bounce back after prolonged use.Unique feeling underfoot

The air trapped in the base means it has a cushion effect underfoot, making it low impact and creating a luxurious living environment. The synthetic material-base can never achieve this.

Disadvantages of natural base (wara-toko)

- Modern buildings have reduced circulation. The air tends to be more humid, so natural base can not breathe and function as it would traditionally, releasing moisture effectively. Without proper ventilation it can develop mold and mites. This being said, it is possible to install it in a modern space if you are committed to care for the tatami in these conditions.

- Price of the natural base (wara-toko) is higher than that of building material-base (kenzai-toko). However, the natural base (wara-toko) is very durable and can be more economical if carefully maintained.

Kenzai-toko (board base). Best feature is its price.

-

The price is lower than wara-toko

Kenzai-toko (board) is made of insulation board – compressed wooden material and polystyrene foam, is cheap and light. It has a market share of 70-80%.

-

The incidence of mites is lower than natural base (wara-toko)

Low incidence rates of bugs and mites, due to its synthetic make-up.

-

Good heat insulating properties

Styrene foam used for the core acts as good heat insulation.

-

Disadvantages of kenzai-toko

- Foam, generally is not very durable. When sewn it doesn’t bounce back like the natural base, this means the tatami needs to be changed every few years.

- Due to its density some people don’t like the feeling underfoot.

- This product has very low humidity absorption so mold is still an issue. (Note: natural base (wara-toko) has a higher propensity for mold.)

Wara-sandwich: Has a similar feeling to natural base

-

Tatami-toko (base) comprised of polystyrene foam sandwiched with wara (straw)

This base is made of polystyrene foam sandwiched between straw. It is light and resistant to humidity also having the added benefit of feeling similar to 100% natural base.

Cost wise it sits between natural base and board. To have this as an option mid-range to top-range order is required.

We are glad to answer any questions and any concerns you have.

Please note the information here is meant to be a guide.

We are happy to offer advice to help you select the best option for your needs, taking into consideration your environment, budget, design, etc. Please don’t hesitate to contact us for further information.