Discover the World of Tatami

About Tatami

Bring Japanese Comfort to

Your Home

Experience the harmony of Japanese craftsmanship and natural living.

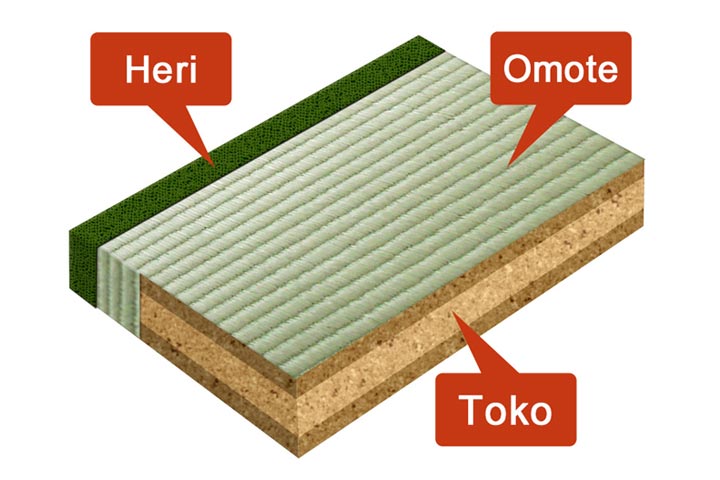

Tatami has been a part of Japanese life for over a thousand years.

Made from natural rush grass (igusa) and rice straw, Tatami reflects the Japanese philosophy of living close to nature.

Its soft texture, subtle fragrance, and warm tone create a sense of calm that invites you to slow down and breathe deeply.

A Living Material that

Connects People and Nature

Tatami is not just a floor ̶ itʼs alive.

It breathes with the seasons: absorbing humidity in summer, retaining warmth in winter, and releasing a gentle scent all year round.

Each mat carries the marks of daily life ̶ a reminder that beauty grows with time and use.

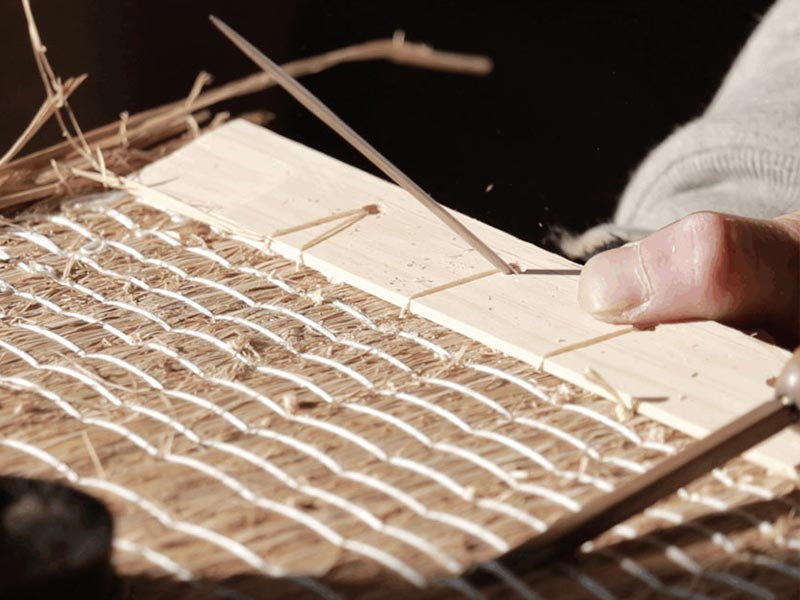

Crafted with Care in Japan

At motoyama tatami, every Tatami mat is handmade by skilled Japanese artisans who carry forward generations of traditional craftsmanship.

We carefully select natural materials, balancing authenticity with modern quality and durability.

Our goal is to bring the quiet comfort of traditional Japanese living into homes around the world.e.

Tatami for Modern Lifestyles

Tatami fits beautifully into any interior ̶ from minimalist apartments to meditation studios and tea rooms.

Whether youʼre creating a relaxing corner for rest, yoga, or tea, Tatami adds a sense of serenity that transforms your space into something truly special.

Discover the Calm of

Japanese Living

Tatami is more than a design choice ̶ itʼs a feeling, a connection, and a return to simplicity. Bring the essence of Japan into your daily life, and rediscover what comfort truly means.